For foundry enterprises, efficient warehouse management is crucial to ensuring fast order delivery and controlling inventory costs. Today, let’s take a look at how an intelligent foundry uses its warehouse "internal capabilities" to hit the "accelerator" for your orders.

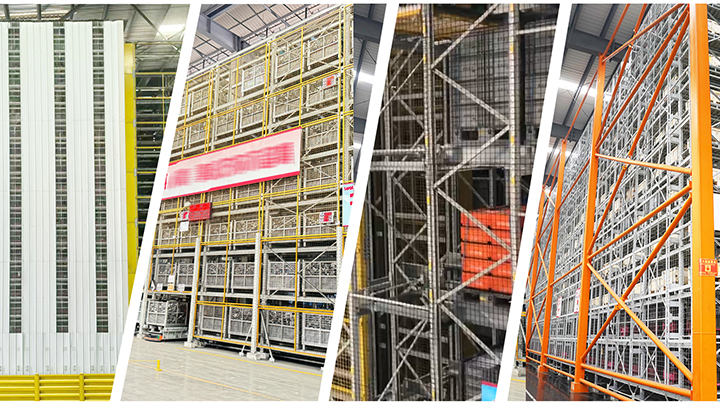

Inside the intelligent factory of Suzhou Ishikawa, 4 advanced automated vertical warehouses have been deployed, forming a "high-speed channel" covering mold preparation, blank casting transfer, and finished product outbound. There is only one core goal: to ensure that the casting products you ordered are delivered to you faster, more accurately, and more stably!

Stepping into our casting workshop, the two vertical warehouses act like "super managers", keeping molds and casting products well-organized.

- Bid farewell to the chaos and inefficiency of mold management in traditional foundries; molds are stored safely and orderly in the intelligent vertical warehouse.

- As soon as an order is placed, the system responds in seconds, intelligently locates the target mold, and retrieves it at high speed.

- Result: Mold preparation time is reduced by more than 70%, ensuring the rapid start-up of the casting production line and significantly shortening the preliminary preparation cycle.

- Newly produced high-temperature castings are temporarily stored here safely and efficiently.

- The system intelligently schedules inbound and outbound operations, and the next process can retrieve castings accurately on demand.

- Result: The backlog and waiting between processes are completely eliminated, the transfer speed of castings is significantly increased, and the overall delivery cycle is accelerated!

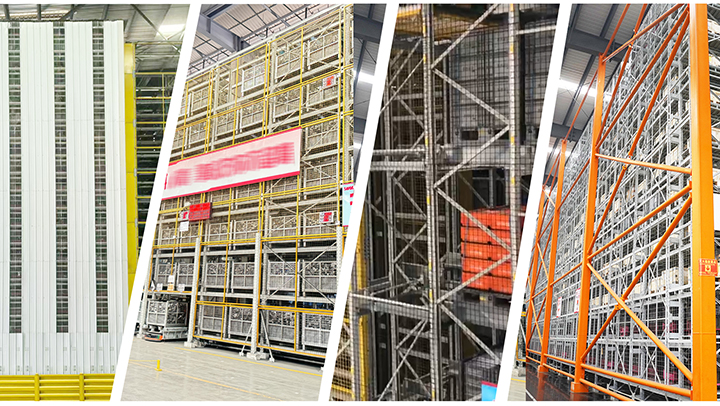

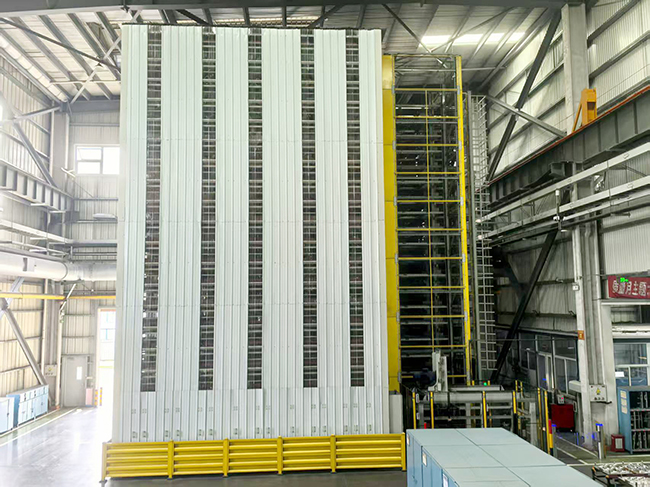

In our processing workshop, the two automated vertical warehouses operate like precisely functioning "intelligent cargo holds", serving different markets accurately.

- Specifically used for storing domestically processed finished parts, with 480 high-level storage locations;

- Core: Efficient "goods-to-person" storage and retrieval! 4-way shuttle cars and RGV handling robots work in synergy;

- Advantage: Whether it is urgent retrieval of small batches and multiple batches, or large-scale centralized warehousing, the system can dynamically allocate storage locations and respond intelligently to real-time needs;

- Result: The turnover efficiency of finished products is more than 3 times higher than that of traditional warehousing!

- Focused on storing processed parts for overseas export, equipped with 2016 dense storage locations;

- Strategy: Supports fixed storage location allocation by model, with the system automatically recording information for accurate positioning in subsequent operations;

- Execution: Stacker cranes complete lifting, translation, storage, and retrieval with millimeter-level precision, and a stable load capacity of 800kg;

- Result: Perfectly balances the needs of high-density storage and high-frequency access.

The realization of such efficient and smooth operations is inseparable from the strong support of the Warehouse Management System (WMS) and Warehouse Control System (WCS). Software provides commands, and hardware executes them—this is how the concept of "speed" is integrated into every link.

The WCS system responds to shipping instructions in real time and automatically plans the optimal path. It accurately dispatches shuttle cars and stacker cranes to work in coordination, greatly improving order processing and shipping speed to ensure customers receive goods faster.

The WMS system tracks detailed cargo information (batch, specification, location) throughout the process and shares key data such as production plans and order delivery dates with the Manufacturing Execution System (MES) in real time. This supports fine-grained inventory management and improves turnover efficiency.

Managers can monitor the real-time and comprehensive dynamics of warehouse inventory and operation status through a visual monitoring screen.

- Shorter delivery cycle: The entire chain—from mold retrieval, blank casting transfer to finished product outbound—is intelligently accelerated.

- More stable quality: Precise management and FIFO (First-In-First-Out) principle reduce human errors, making the traceability of casting batches and quality more reliable.

- Continuous optimization of comprehensive costs: Maximized space utilization, streamlined labor, reduced product backlogs and material waste, and minimized handling—all contributing to cost reduction and efficiency improvement.

This intelligent management model not only makes warehouse operations more efficient and accurate but also provides a solid data foundation for production planning and order decision-making, creating greater value for customers.